POLISHED CONCRETE

CONCRETE POLISHING SERVICES

Polished concrete is a relatively new green flooring option that has great durability and low maintenance costs. It is the ideal flooring solution for areas with heavy cart and foot traffic. Whether in a commercial or industrial setting the look of your concrete floor can be fully customized using minimal to aggressive grinding, different levels of sheen, stains and stencils.

We provide commercial and industrial concrete floor polishing services throughout Southern California. Be sure to check out our photo gallery below.

High quality work with competitive pricing contact us for your free estimate!

WHY POLISHED CONCRETE?

- Superior Durability- Will stand up to heavy traffic

- Low Maintenance- Clean with a dust mop or ph neutral floor cleaner.

- Increased Slip Resistance- Less slippery than epoxy or wax

- Improved Reflectivity- Level of gloss can be customized from a matte to a high gloss finish

- Increased Stain Resistance- The use of concrete densifiers and sealers can provide an extended window of opportunity to clean spills without staining

- Eliminate Dusting- No more concrete dust on products or equipment. *We can also dustproof without polishing

- Reduced Tire Wear- Great for areas with high forklift traffic

- No Production or Plant Shut Downs- Dust collection systems keep workers safe. Night work available.

- Customizable Look- Can be stained, stenciled and engraved

WHO'S INSTALLING?

- Warehouses

- Retail Stores

- Industrial Facilities

- Restaurants

- Hotels

- Schools

- Auto Dealerships

- Examples of polished concrete can be seen on every floor at Home Depot, Lowes or Costco. Many Walmart and Target stores are also making the switch to polished concrete

THE PROCESS

Concrete polishing requires the use of large walk behind floor grinders equipped with various grit diamond tools that will grind and refine the concrete surface. The refinement process of these diamond tools will make the concrete itself shine. The starting diamond grit size must be followed in order (30 grit, 50 grit, 100 grit, etc.) until the desired stopping point/sheen is reached, typically 800 grit. Our typical polishing system requires us to grind the entire floor 6 times (50-800grit), concrete densifier application and guard/sealer application. Each floor is unique and may require more or less steps to produce your desired look.

The initial grind is the most important and time consuming step. This is typically done starting with 14 grit, 30 grit or 50 grit diamond tools. The condition of the concrete or desired aggregate exposure level will determine the appropriate starting grit. The lower the grit, the slower the tools must be ran to reach full refinement. Starting with a 14 grit will signifigantly increase the duration of a project and expose more aggregate than starting with a 50 grit. Each floor is different but a 50 grit diamond will typically remove the surface cream and expose the fine/sand aggregate.

Once the initial grinding is complete we typically run 100 through 800 grit diamond tools. We can go up to 1,500 or 3,000 grit if a higher gloss level is desired. Stopping at 100 or 200 grit will typically produces a matte or very minimal sheen. A 400 grit typically produces a satin to semi gloss sheen. The 800 grit diamonds will produce the most dramatic change in the appearance of the concrete. The concrete will typically have a gloss sheen with good reflectivity. Running 1,500 or up to 3,000 grit diamond tools will increase the clarity of the reflections in the concrete.

Once the refinement process is complete the floor is then sealed using a semi penetrating sealer, fully penetrating sealer or a combination of both. The sealer application is for stain protection only but will slightly enhance the sheen of the concrete. The fact that the concrete itself has a shine from the grinding/polishing process is what makes it so durable. While we like to let the sealer cure overnight, floors can be returned to service within a few hours of completion.

Polished concrete is not a light buff, wax or coating.

PRO SHINE DIFFERENCE

We are not new to the polished concrete industry. We have extensive experience with commercial and industrial concrete floors. This allows us to be upfront with our customers on the ability to achieve their desired finished look. We own all of our equipment which is thoroughly maintained to increase safety, productivity and decrease down time. We hold certificates for concrete polishing from many industry leading companies including Lavina- Superabrasive , Ameripolish, HiTech Systems and Concrete Polishing HQ. We continue to attend training courses from equipment and chemical manufacturers to stay up to date with new industry products and trends. We have the experience and knowledge to provide you with beautiful, durable polished concrete floors. Don't hesitate to contact us for your free estimate.

COLORING

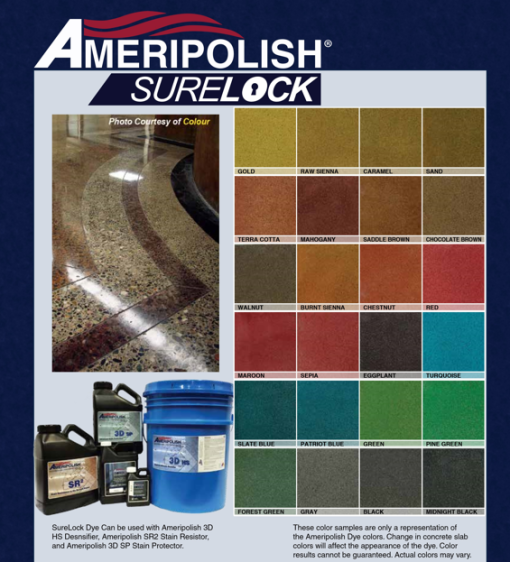

Ameripolish Surelock Dye- Interior Polished Concrete

This product comes concentrated and can be mixed with acetone or water depending on your projects needs. Acetone based dye is slightly more vibrant than waterbased and dries extremely fast. It is used when applying multiple colors to strencils/logos or when an extremely fast dry time is necessary. Water based dye can be used for single color applications and can be used when solvent based products are not an option. This product is applied in conjunction with concrete densifier and concrete sealer.

MAINTENANCE

While polished concrete requires minimal maintenance, it is not a maintenance free flooring. Daily cleaning is typically done using a dry dust mop or wet mop depending on the environment. Cleaning your floor with a professional piece of equipment like an autoscrubber and high speed burnishing is sometimes all it takes to bring your floors shine back. Some floors may require sealer reapplication and sometimes joint fillers need to be removed and replaced.

When using a chemical cleaner on your concrete floors always make sure that it is concrete safe and pH neutral!

Pro Shine can provide you with the services you need to make your concrete look like the day it was finished. Contact us today!

Service area keywords- Riverside County, Orange County, San Bernardino County, Riverside, Corona, Eastvale, Norco, Canyon Lake, Lake Elsinore, Moreno Valley, Perris, Menifee, Murrieta, Grand Terrace, Highgrove, Loma Linda, Yucaipa, Calimesa, Banning, Beaumont, Hemet, Chino, Chino Hills, Fontana, Ontario, Pomona. Rialto, Colton, San Bernardino, Redlands, Rancho Cucamonga, Yorba Linda, Anaheim Hills, Anaheim, Orange, Fullerton, Irvine, Costa Mesa, Newport Beach, Huntington Beach, Southern California